If your application requires electrical, biological or environmental protection, Parylene can provide the critical properties and meet tight parameters that other coating options cannot deliver.

Thin film Parylene polymer is considered the optimal protective coating material for critical military, high-risk electronics, aerospace, and medical applications because of its unique combination of electric-mechanical properties and true pinhole-free nature. These properties include gas permeability, chemical protection, thermal stability across environments, and extremely high dielectric strength.

Parylene exhibits absolute conformance to all surfaces due to the deposition method. The three-stage vapor deposition process takes place under a vacuum with substrates being coated at room temperature. Unlike traditional conformal coating methods, there is no liquid phase or lengthy curing time involved.

Learn more:

Parylene is unlike other conformal coatings because it is applied as a vapor. The unique application process allows it to thoroughly cover the entire surface of a PCB. In a room temperatures space, the deposition is used and grows on the electronic component. Plastics, ceramics, metals, and fabrics can all have parylene applied to them.

As electronics begin to grow smaller in size parylene is taking a lead role in conformal coatings. When applied, it is thinner than a dollar bill or even human hair. When it comes to choosing a conformal coating, most industry experts will favor parylene.

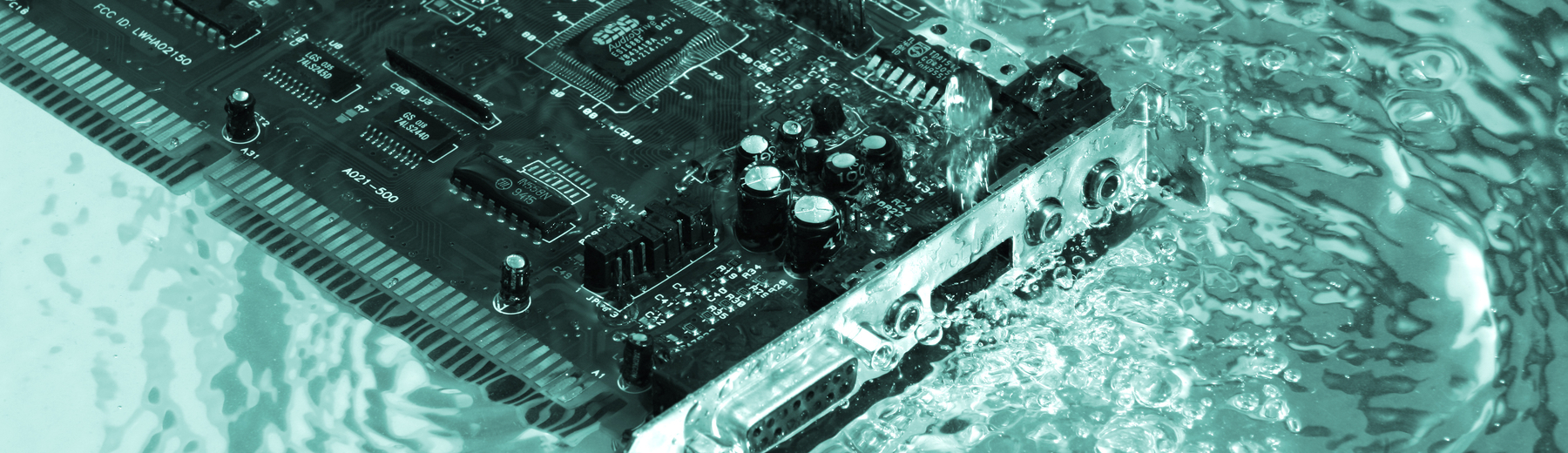

A parylene conformal coating is applied to an electronic PCB that needs protection from exposure to environmental threats such as dust, temperature, and moisture. Conformal coatings can also protect the exposition of PCBs in fraught situations. Sometimes these are electrical currents, mechanical forces, or chemicals. The protection will prevent corrosion and oxidization. It can also extend the life of an electronic.

It’s important to look at the drawbacks of a liquid coating such as epoxy, silicone, and acrylics. Liquid coatings are applied through a dip or spray process and then cure after. Unlike parylene which cures uniformly in a micro-thin layer, liquid applications can be uneven leaving potential pinholes that expose the PCB. Liquid coatings also contain additives that reduce the durability and continue to gas off after application.

Since there is such a wide variety of conformal coating types, it's important to understand what makes parylene stand out. Parylene is a reliable, long-lasting coating that goes on clear and pinhole-free--not to mention it can be controlled closely for thickness and can coat even the most awkward or unusual shapes and areas. This is made possible because of a few unique details in the way parylene is applied and used. Here's what the parylene experts noticed when comparing parylene to other conformal coatings.

Parylene is placed with a unique chemical vapor deposition process, which is why this conformal coating can so reliably coat even the most difficult areas. The coating goes on lightweight and is placed in layers of varying thickness, so there will never be too much or too little protection--all without adding significant mass that could interrupt the function of the product. This is one of the reasons parylene is the first choice.

One of the reasons why parylene is so widely used is that it comes in different types, meaning that there is a type of parylene for every job. Parylene N provides high dielectric strength and a dielectric constant that does not vary with changes in frequency. Best selection where greater coating protection is required. Parylene C provides a combination of properties, plus a very low permeability to moisture, chemicals, and corrosive gasses.

At the end of the day, parylene is favored over other conformal coatings because it's good at what it does. It can survive high temperatures and other extreme conditions, it protects against everything from chemicals to moisture, and it remains strong and reliable.

Parylene is used just about everywhere for a little bit of everything and considering its long list of benefits and positive characteristics, it's no surprise that experts in every field turn to parylene coating first.

The unique benefits of Parylene make it more effective in optimizing critical system dependability than any other coating. Investing in this premier coating can yield substantial long-term warranty cost savings compared to less effective materials.

There are many careful steps involved in effectively managing the Parylene coating process. Advanced Coating has the experience needed to successfully handle high-risk assemblies and maximize the performance of this sophisticated material across a wide range of applications.

Advanced Coating

10723 Edison Court

Rancho Cucamonga, CA 91730

Phone: 800.722.1444 | Fax: 909.481.1427

©2021 Advanced Deposition & Coating Technologies, Inc.

Terms of Use • Privacy Policy