Parylene polymers are deposited from the vapor phase by a process in which all sides of an object to be encapsulated are uniformly impinged by the gaseous monomer at pressures at around 10 to 30 mTorr (Millitorr).

The ultra-thin Parylene film is formed by the pyrolysis of a di-p-xylene (dimer) in a vacuum environment which is then deposited on a cooler (i.e. room temperature) substrate inside the deposition chamber while under continuous vacuum.

The three-phase vapor deposition of Parylene polymer allows it to be formed as a structurally continuous film which is truly conformal to the design and structure of the substrate upon which it is being deposited.

Parylene can be effectively deposited with excellent accuracy in thickness over a range from 0.2 µm (microns) to well over 8 mils.

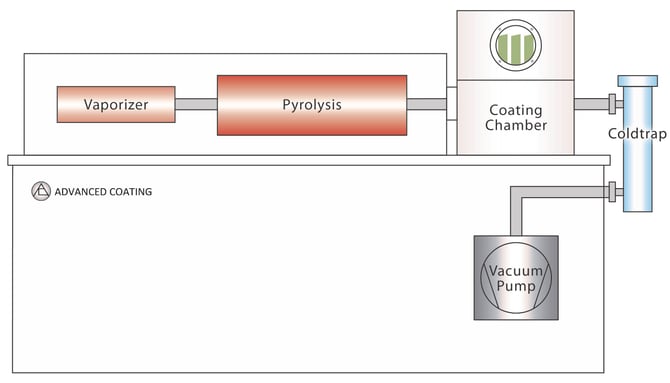

The Dimer is added to the Vaporizer and is heated to 75-250 degrees Celsius depending on application and Parylene type. The dimer turns from a powder into a vapor.

The Dimer is heated up further in the furnace at 600 – 700 degrees Celsius and becomes a monomer.

Dimer turns into a polymer that adheres evenly as transparent Parylene film to the components inside the coating chamber at ambient temperature.

The Cold Trap collects and condenses excess monomer from vacuum chamber and the Vacuum Pump maintains constant vacuum throughout the process.

The Parylene coating process does not include any liquid phase and there is no traditional curing time involved.

Our parylene coating experts know that, while "the science side" of the deposition process is important, there is a necessary artistic touch that's just as crucial. Here's a quick look!

Advanced Coating has decades of Parylene coating experience and can design an ultra-thin protective coating that meets your unique specifications. Let us guide you through the process to ensure your 100% satisfaction.

Advanced Coating

10723 Edison Court

Rancho Cucamonga, CA 91730

Phone: 800.722.1444 | Fax: 909.481.1427

©2021 Advanced Deposition & Coating Technologies, Inc.

Terms of Use • Privacy Policy