There are many techniques available for removing parylene conformal coating, but not all were created equal. Today we'll compare some of your top options for parylene removal and help you decide which choice is right for your job.

There are many techniques available for removing parylene conformal coating, but not all were created equal. Today we'll compare some of your top options for parylene removal and help you decide which choice is right for your job.

The Trouble with Coating

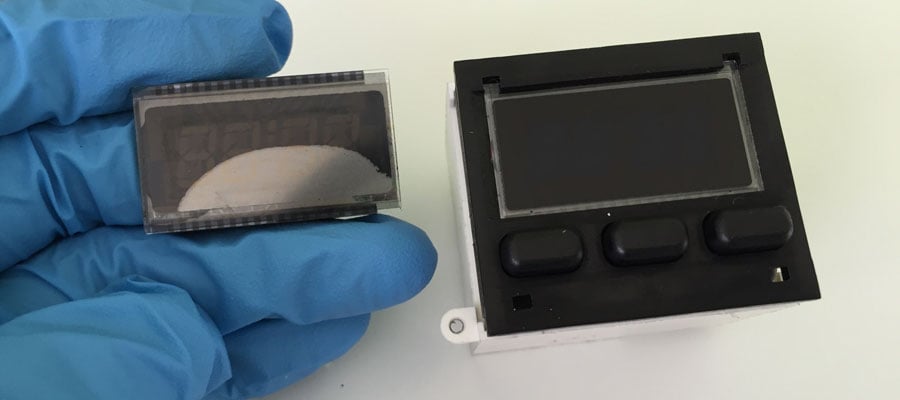

Parylene conformal coating has become increasingly popular across a range of industries, thanks to its exceptional physical, thermal, and chemical properties. Its ability to withstand extreme conditions and its clear, pinhole-free nature make it an ideal choice for applications in aerospace and medical apparatus.

However, while the reliability and longevity of parylene coating are advantageous, removing the coating can be a challenge. To address this issue, it is crucial to carefully consider and select the most suitable removal technique based on the specific needs and requirements of your project.

Solvent vs. MicroBlasting vs. Thermal

There are several commonly used methods for removing parylene, including solvent, microblasting, and thermal techniques. Each method has its own advantages and considerations to take into account.

Solvent Removal

Solvent removal, for example, requires precise specifications and careful expertise due to the chemically inert nature of parylene. However, with the right tools and knowledge, solvent removal can be a safe and effective option.

MicroBlasting Removal

Microblasting removal, on the other hand, has gained popularity for its effectiveness and minimal risk. This technique allows for the removal of very small or specific coverage areas, making it the preferred choice in situations where only certain regions of parylene need to be removed while leaving the rest undamaged.

Thermal Removal

Thermal removal, although involving a certain level of risk, can be an efficient choice for targeted removal of parylene from specific areas. It is important to note, however, that thermal removal exposes the object or substrate surface to high levels of heat, which may not be suitable for items containing sensitive electronics.

Considering the unique requirements and constraints of your project, it is advisable to consult professionals or experts in conformal coatings and parylene removal. They can provide guidance and assist you in selecting the most appropriate technique.

If you are interested in learning more about conformal coatings or parylene removal, feel free to contact us today! We are here to provide you with the information and assistance you need to make informed decisions for your specific application.